Harnessing Environmental Product Declarations for Sustainable Stone Selection

In today’s rapidly evolving construction landscape, architects, builders, and interior designers are increasingly recognizing the importance of sustainability. One key area that’s gaining traction is the integration of Environmental Product Declarations (EPDs) into the material selection process. By leveraging EPDs, design professionals can make informed decisions, reduce the environmental footprint of their projects, and align with green building certifications.

Let’s take a look at EPDs and how architects and builders can effectively use them for stone specification, with a special focus on the offerings available on the Polycor website.

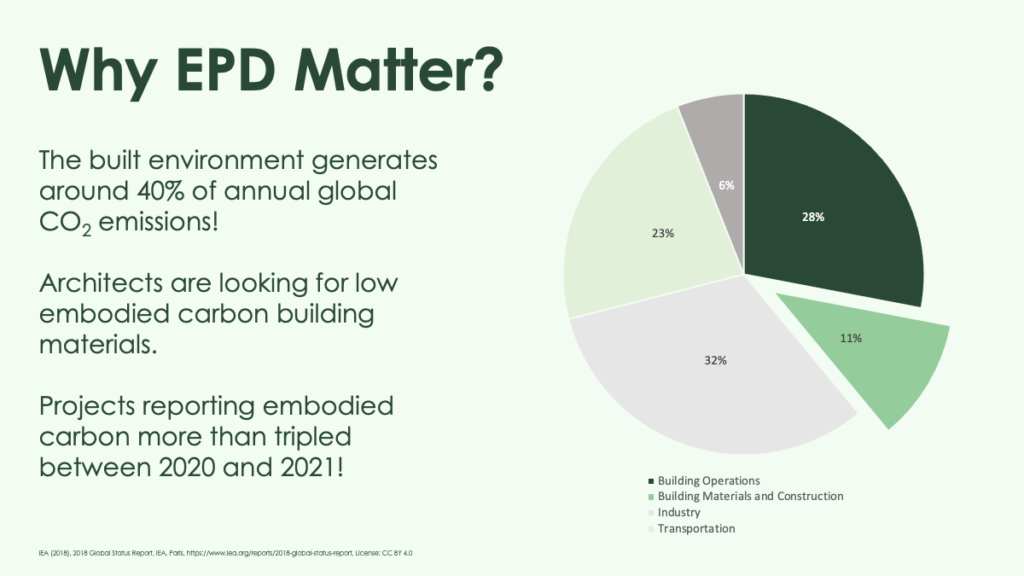

Understanding EPDs and Why They Matter

The built environment generates around 40% of annual global CO2 emissions and architects, city planners and governments are looking at different strategies to address this issue. One of them is to choose low-embodied carbon building materials

In this regard, Environmental Product Declarations (EPDs) are robust documents that quantify a product’s environmental impact across its entire life cycle. They offer transparent and science-based insights into factors such as global warming potential (GWP) which refers to energy consumption and resource depletion. EPDs are designed to provide architects and builders with actionable data for making sustainable material choices. By incorporating EPDs, professionals contribute to a more eco-conscious construction industry.

It’s important to recognize the differentiation between two types of EPDs: the “Industry Wide” EPD and the “Product Specific” EPD (also known as “Company Specific”). Related to the stone industry, the former provides averages across stone types like marble, granite, and limestone. In contrast, the latter is specific to a particular product or company, such as Polycor, and offers more precise data based on our distinct marble, limestone, granite, and other products. This “Product Specific” EPD exclusively considers Polycor’s data points, ensuring a more accurate reflection of the environmental impact.

Industry Wide EPD vs Individual EPD

Many building material manufacturers, including Polycor, provide EPDs, allowing architects and builders to make more educated, informed decisions when selecting materials for a project. Architects and builders can use EPDs to make well-informed decisions because they provide a clear understanding of a stone’s environmental performance, helping professionals assess its impact on the planet. Plus, EPDs support green building certifications such as LEED®, BREEAM, and Living Building Challenge, aiding in the pursuit of green building goals.

While many use EPDs to compare different building material products and identify those with lower environmental footprints, that’s not what they are ultimately designed for.

“Even though EPDs are intended to bring greater transparency to products, it is not uncommon for them to be used to compare products to one another. It’s a little challenging, because the analysis for different products varies across industries, so you’re not always looking apple to apple.”

While EPDs offer a wealth of information, professionals must be aware of challenges such as varying data accuracy. To address these, rely on verified EPDs from reputable sources like Polycor’s website and engage with knowledgeable experts.

Exploring the Polycor Advantage

The new sustainability pages on the Polycor website offer an invaluable resource for architects and builders seeking sustainability-driven stone choices.

The performance dashboard for each product provides a quick, high-level snapshot of a product’s overall sustainability. However, the real data and metrics lie within the deeper sections of the EPD, including:

- Features & Functionality: Discover how the stone performs under different conditions and learn about its unique characteristics.

- Environment & Materials: Gain insights into the stone’s environmental attributes, including its origins, material composition, and potential impacts.

- Certifications & Rating Systems: Understand the stone’s alignment with sustainability certifications and industry standards.

- Life Cycle Assessment (LCA) Results & Interpretation: Delve into the stone’s life cycle impacts, including its carbon footprint, energy use, and resource consumption.

Interpreting LCA Data for Sustainability

EPDs include Life Cycle Assessment (LCA) data, a cornerstone of understanding a product’s environmental impact. Key LCA measurements include:

- Acidification of Land and Water Resources: Evaluate the impact on ecosystems and water bodies.

- Eutrophication: Assess nutrient levels in water and their potential to cause ecological imbalances.

- Global Warming Potential (Embodied Carbon): Understand the carbon emissions associated with the stone’s life cycle.

- Ozone Depletion and Resource Use: Analyze depletion of ozone layer and consumption of resources like fossil fuels.

“The LCA’s have to be developed first. They set the guardrails.” – Ralph Morgan, Director of Environment & Sustainability

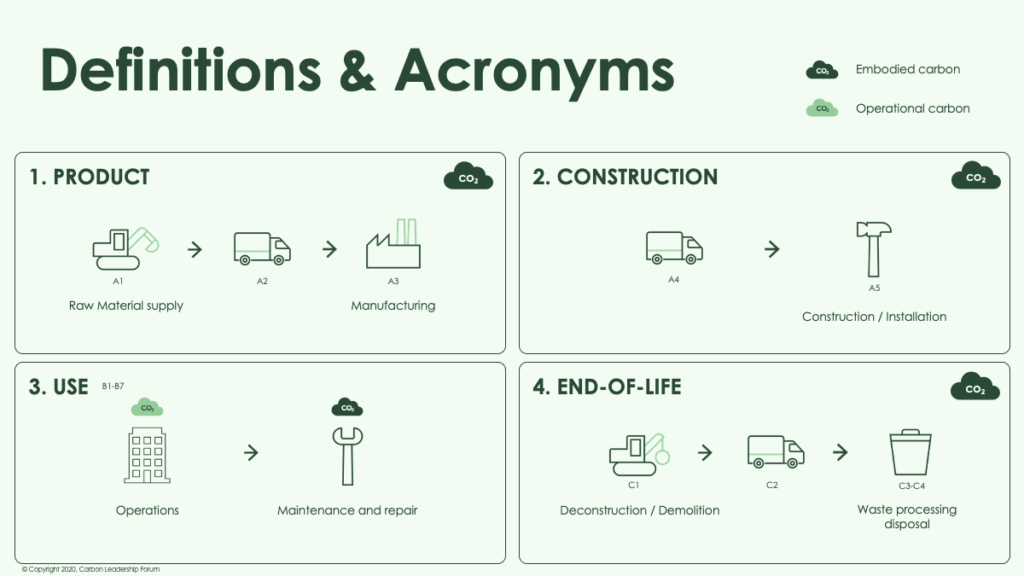

To understand the total impact of the product through all life cycle stages, Polycor utilizes a cradle-to-grave approach in conducting the LCA. Cradle-to-grave addresses the environmental aspects and potential environmental impacts throughout a product’s life cycle from raw material acquisition, including its overall service life, down to the end-of-life after it is uninstalled.

Some industries may decide to not go with the full life cycle analysis and instead utilize only a cradle-to-gate approach, such as the concrete industry. This simply measures the life cycle from raw material acquisition up until it leaves the “gate” of the factory and nothing further.

For example, if stone cladding is removed from a building a portion after its service life it may be landfilled, and the rest may be recycled. This is accounted for in all of Polycor’s EPDs. End of life contributes very little to natural stone’s overall environmental impacts because it is inert and returns back to the earth in its original form, the way it came out.

“We are completely vertically integrated — we pull the block out and even if we sell to a fabricator they’re buying that block, nothing’s added to it,” said Ralph. “There is no manufacturing in natural stone. There’s only fabrication.”

By including all life cycle stages, more information becomes available for understanding how to reduce impacts. When you consider all the stages, you can learn how the product performs during the installation phase, the use phase, and the end-of-life.

Case Study

The Sustainable Advantages of Indiana Limestone: A Case Study of Freedom Place

In a world where sustainability is paramount, EPDs provide design professionals with a powerful toolkit for responsible stone specification. By navigating the performance dashboards for each product and delving into the depths of information on the Polycor website, professionals can seamlessly integrate sustainability considerations into their projects.

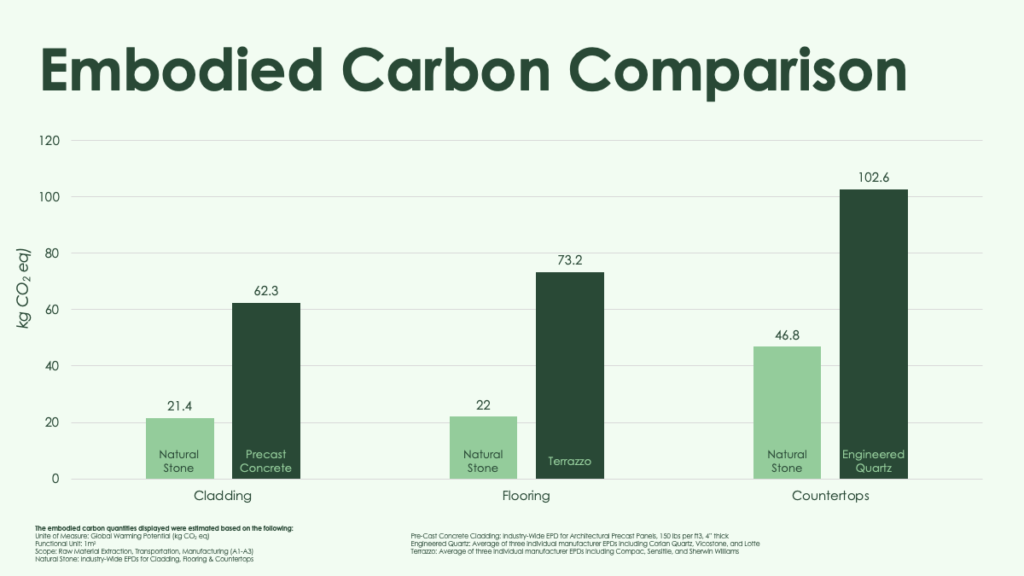

By offering one of the lowest embodied carbon materials on the market, Polycor natural stone products play a key role in its sector to help architects and builders reach their environmental goals. EPDs empower decision-makers to make choices that are not only architecturally inspiring but also environmentally responsible. As architects, interior designers, and builders tread the path to a greener future, EPDs light the way towards a construction industry that embraces sustainability with open arms.

Want to learn more? Download Product-Specific EPDs and other sustainability-related resources from Polycor’s website by clicking the link below.